Understanding the Benefits of Laser Marking Technology in Modern Manufacturing

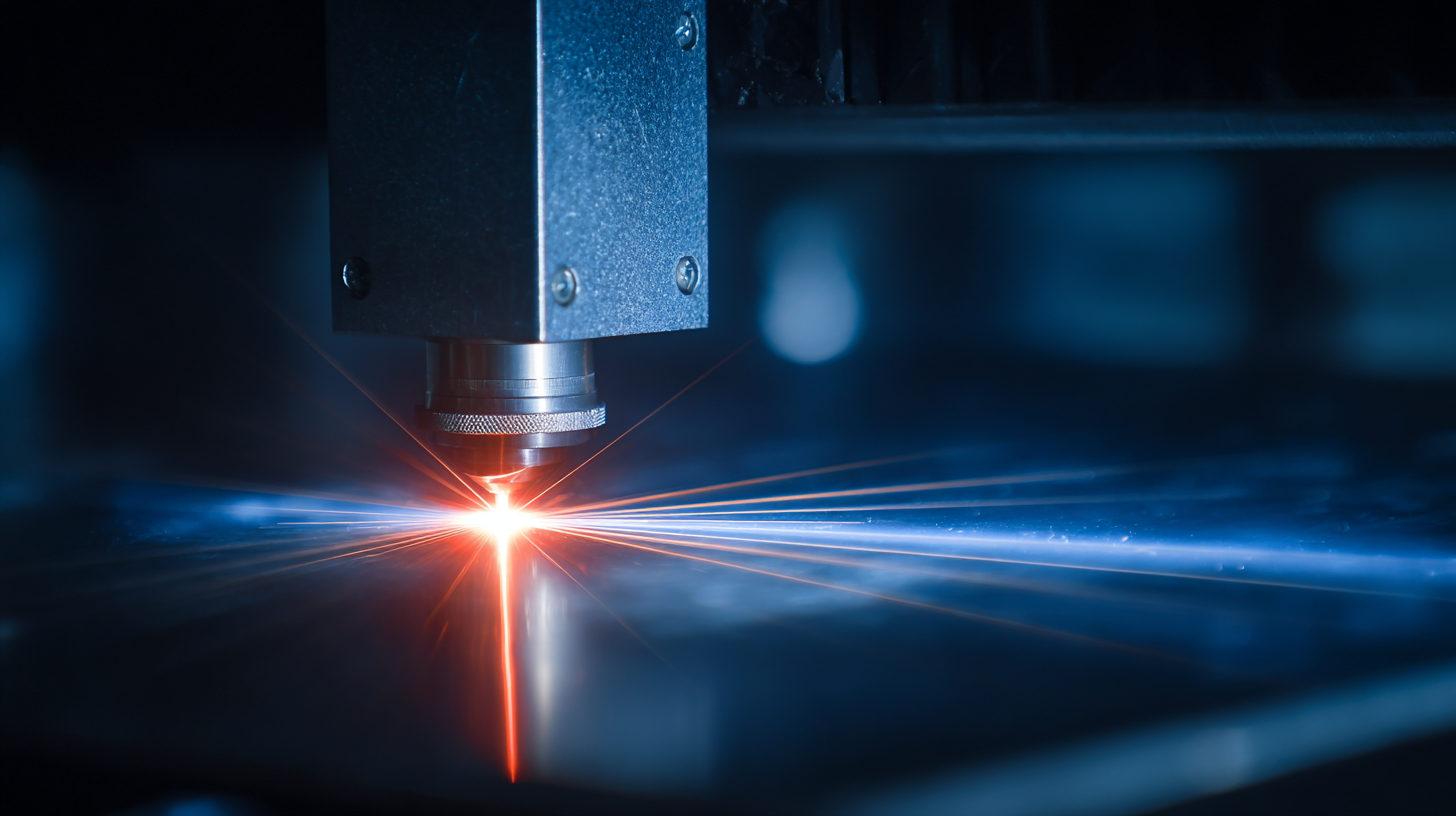

In the ever-evolving landscape of modern manufacturing, technological advancements play a crucial role in improving efficiency, precision, and product quality. One such advancement that has gained significant traction is laser marking technology. This innovative method utilizes focused laser beams to create permanent marks on various materials, offering numerous benefits over traditional marking techniques. By understanding what laser marking entails and its applications, manufacturers can leverage this technology to enhance their production processes. From improving traceability and branding to providing high-speed marking without contact, laser marking is a game-changer in the industry. This article explores the manifold advantages of laser marking technology, demonstrating how it can optimize manufacturing workflows and ultimately contribute to greater competitiveness in the market.

Overview of Laser Marking Technology in Manufacturing

Laser marking technology has emerged as a pivotal tool in modern manufacturing, offering precision and versatility across a range of industries. Utilizing various types of lasers, including fiber, CO2, and UV lasers, this technology enables manufacturers to mark, engrave, and etch materials with high accuracy. The adaptability of laser marking means it can be applied to metals, plastics, and even organic materials, catering to diverse product requirements.

The market for laser marking machines is witnessing significant growth, driven by the rising demand for high-quality marking solutions in industrial applications. Businesses are increasingly leveraging fiber and solid-state lasers due to their efficiency and optimal performance in marking permanent designs on components. As industries move towards automation and personalized products, the integration of laser marking technology becomes essential for enhancing productivity while maintaining cost-effectiveness. As manufacturers embrace these advancements, understanding the benefits of laser marking will be crucial for staying competitive in the evolving landscape of manufacturing.

Understanding the Benefits of Laser Marking Technology in Modern Manufacturing

| Dimension | Details |

|---|---|

| Precision | High accuracy with minimal tolerance levels, suitable for intricate designs. |

| Speed | Rapid processing compared to traditional marking methods, improving production efficiency. |

| Material Versatility | Applicable on a wide range of materials including metals, plastics, and ceramics. |

| Permanent Marking | Creates durable marks that resist abrasion and fading over time. |

| Eco-Friendly | Utilizes less energy and generates no harmful chemicals compared to traditional methods. |

| Customization | Allows for easy personalization and design modifications, catering to specific customer needs. |

Key Advantages of Implementing Laser Marking in Production Processes

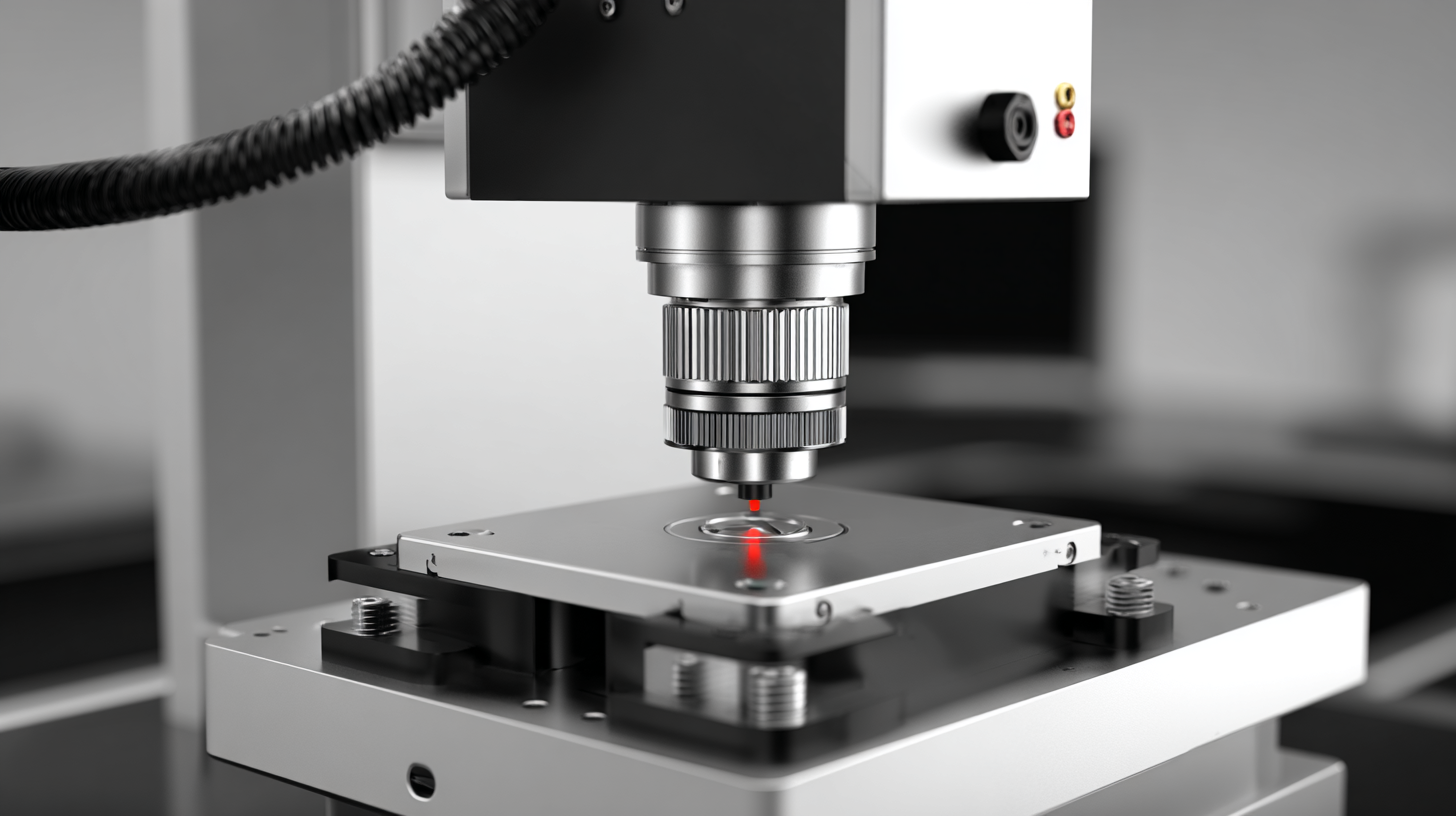

Laser marking technology has transformed modern manufacturing, offering key advantages that enhance production processes significantly. One of the primary benefits is precision. According to a report by Research and Markets, the global laser marking market is projected to reach $4 billion by 2026, reflecting the increasing adoption of this technology. With laser marking, manufacturers can achieve intricate designs with an accuracy of up to 0.01 mm, ensuring that each component meets exact specifications.

Another critical advantage is speed. Laser marking systems can mark up to 1000 parts per hour, greatly accelerating production lines compared to traditional marking methods. This efficiency leads to reduced labor costs and shorter lead times. Also, since laser marking is a non-contact process, it minimizes wear on both the machinery and the products, leading to longer equipment durability and reduced downtime.

Tips: When implementing laser marking technology, consider investing in a system that offers versatility in marking different materials, from metals to plastics. Additionally, regular maintenance of the laser equipment can ensure optimal performance and longevity, ultimately contributing to greater production efficiency.

Comparative Analysis: Laser Marking vs. Traditional Marking Techniques

Laser marking technology has revolutionized the way products are labeled and identified in modern manufacturing. Unlike traditional marking techniques such as inkjet printing or stamping, laser marking offers enhanced precision and durability. One of the primary benefits of laser marking is its ability to create high-quality, permanent markings on a variety of materials without the risk of smudging or fading. This makes it particularly advantageous for products that require long-lasting identification, such as medical devices and automotive parts.

Additionally, laser marking is significantly more efficient and environmentally friendly than its traditional counterparts. It eliminates the need for consumables like inks and pastes, reducing waste and contamination. Manufacturers can also benefit from greater flexibility, as laser systems can be easily adjusted to accommodate different materials and production runs.

Tips: When considering a transition to laser marking, evaluate the specific materials you use and the required marking intricacies. It’s also wise to conduct a cost-benefit analysis, as the upfront investment in laser technology can yield significant savings and quality improvements in the long run. Implementing a pilot project can help determine the best laser system for your needs.

Applications of Laser Marking Across Various Industries

Laser marking technology is increasingly becoming indispensable across various industries due to its unparalleled precision and versatility. In sectors such as automotive, electronics, and consumer goods, manufacturers are adopting laser systems to meet the rising demand for high-quality marking. According to a recent industry report, the global laser marking market is projected to grow at a CAGR of 5.4% from 2021 to 2026, underlining the technology’s expanding role in manufacturing processes.

Laser marking technology is increasingly becoming indispensable across various industries due to its unparalleled precision and versatility. In sectors such as automotive, electronics, and consumer goods, manufacturers are adopting laser systems to meet the rising demand for high-quality marking. According to a recent industry report, the global laser marking market is projected to grow at a CAGR of 5.4% from 2021 to 2026, underlining the technology’s expanding role in manufacturing processes.

In the automotive industry, for instance, laser marking is essential for permanent part identification and traceability, ensuring compliance with strict regulatory standards. The ability to mark intricate designs and codes on various materials, including metals and plastics, means companies can enhance their operational efficiency while reducing the risk of errors. Similarly, the electronics sector benefits from laser technology's capacity to provide fine details and high contrast, crucial for components requiring precise identification and branding.

Moreover, advancements such as ultra-fast laser marking systems are being developed to streamline production lines, significantly boosting throughput without compromising accuracy. Such innovations reflect the ongoing commitment within the manufacturing sector to leverage cutting-edge laser technologies to enhance product quality and operational efficiency, aligning with the demands of modern consumers.

Future Trends in Laser Marking Technology and Its Impact on Manufacturing

The future of laser marking technology in manufacturing is poised for significant transformation, driven by the ongoing shift towards automation and smart manufacturing. As industries increasingly recognize the advantages of integrating laser marking into their operations, the global market for such technologies is expected to expand substantially. Advances in fiber laser technology, particularly, are enhancing production efficiency, reducing costs, and improving product quality. These innovations not only streamline manufacturing processes but also ensure compliance with stringent regulatory requirements, making them essential for modern logistics and product traceability.

As the global industrial automation market is projected to experience a robust compound annual growth rate of 9.8% from 2022 to 2029, laser marking will play a crucial role in this momentum. The growing demand for automated solutions is redefining how products are manufactured and identified, with a notable emphasis on precision and reliability. Laser marking technology is anticipated to evolve further, with trends indicating increased integration with Internet of Things (IoT) systems, fostering real-time data exchange and enhanced operational insights. As manufacturers embrace these trends, laser marking stands out as a critical component in their journey towards operational excellence and industry leadership.

Related Posts

-

Unlocking Precision and Efficiency with Handheld Laser Welders in Modern Manufacturing

-

Unlocking the Future: How Micro Welders Are Revolutionizing Precision Manufacturing

-

Exploring the Advantages of Hand Held Laser Welding Machines: Efficiency and Precision Unleashed

-

Exploring the Future: How Handheld Laser Welders Are Revolutionizing DIY Projects

-

Revolutionizing Manufacturing: How Welding Automation Increases Efficiency by 30% and Reduces Costs