Unveiling the Future: How Laser Welders Revolutionize Modern Manufacturing Techniques

In the rapidly evolving landscape of modern manufacturing, laser welders have emerged as a pivotal technology, significantly enhancing production efficiency and quality across various industries. According to a recent report by MarketsandMarkets, the global laser welding market is projected to reach $2.5 billion by 2025, growing at a CAGR of 4.5% from 2020. This surge can be attributed to the increasing demand for precision in fabrication processes in sectors such as automotive, aerospace, and electronics, where even minute discrepancies can lead to costly failures.

Laser welders are not only capable of delivering high-speed processes but also ensure minimal thermal distortion, thereby improving the durability of the welds. As manufacturers seek to innovate and optimize their workflows, the integration of laser welding technology is becoming indispensable, marking a transformative shift in production methodologies and output quality.

Exploring the Basics of Laser Welding Technology in Modern Manufacturing

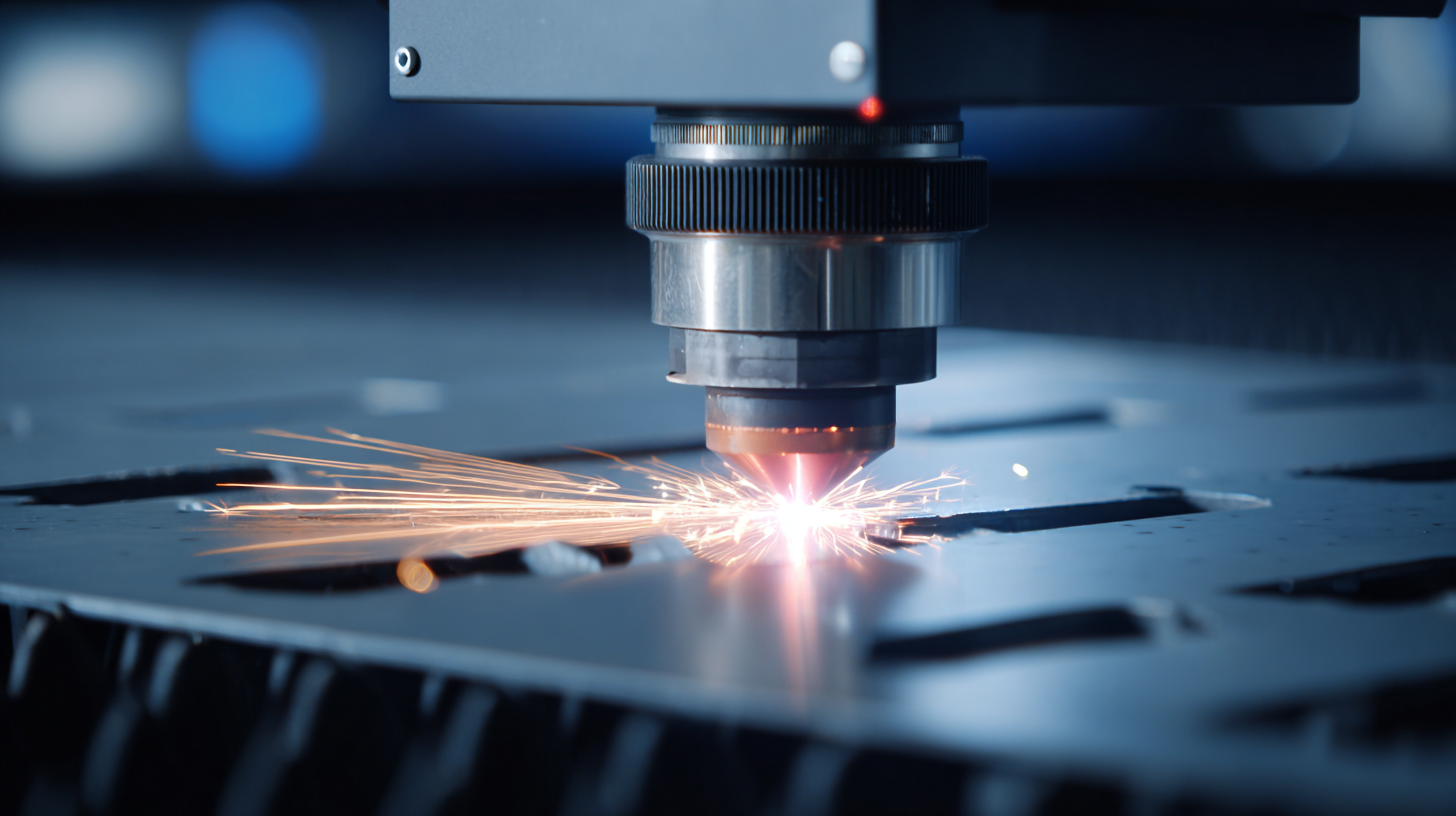

Laser welding technology has emerged as a transformative force in modern manufacturing, offering precision and efficiency that traditional welding methods struggle to match. At its core, laser welding utilizes a focused beam of light to melt and fuse materials, resulting in strong, clean joins. This method is particularly advantageous in industries where high accuracy and minimal heat input are critical, such as aerospace, automotive, and medical device manufacturing. The ability to control the laser parameters allows manufacturers to tailor the welding process to specific applications, enhancing production quality and speed.

Moreover, the versatility of laser welding techniques enables a broader range of materials to be joined effectively, including metals, plastics, and advanced composites. The process generates less distortion and reduces the risk of introducing impurities, making it ideal for high-performance applications. As industries continue to adopt laser welding technology, they benefit from shorter lead times, reduced material waste, and ultimately, lower production costs. This innovative approach not only streamlines manufacturing workflows but also paves the way for the development of new products and solutions in an increasingly competitive market.

Understanding the Benefits of Laser Welders Over Traditional Welding Methods

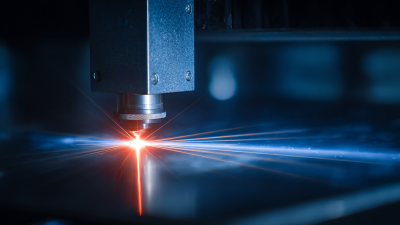

Laser welders are transforming modern manufacturing by offering numerous advantages over traditional welding methods. One significant benefit is precision. Unlike conventional welding that often requires extensive cleanup and finishing, laser welding provides a focused heat source that allows for tighter control over the weld pool. This high degree of accuracy results in cleaner seams, reducing the need for additional processes and improving the overall quality of the final product.

Another notable advantage is speed. Laser welding can significantly shorten production time due to its fast operation, allowing manufacturers to increase throughput without sacrificing quality. This efficiency is particularly beneficial in industries where time-to-market is critical. Furthermore, laser welding produces less heat-affected zone (HAZ), minimizing warping and distortion in the materials being welded, which is a common issue with traditional techniques.

**Tips for Implementation:** When considering the switch to laser welding, companies should assess their specific manufacturing needs and explore various laser systems. Investing in training for operators is essential to harness the full potential of this technology. Additionally, it's crucial to regularly maintain the equipment to ensure optimal performance and longevity.

Unveiling the Future: How Laser Welders Revolutionize Modern Manufacturing Techniques

| Welding Method | Advantages | Limitations | Common Applications |

|---|---|---|---|

| Traditional Welding | Cost-effective, widely available, versatile | Heat affected zone, safety hazards, slower speed | Construction, repair, heavy machinery |

| Laser Welding | Precision, minimal heat affected zone, fast processing | Higher upfront cost, requires skilled operation | Aerospace, automotive, medical devices |

| TIG Welding | High quality, precise control, suitable for thin materials | Slower speed, more labor-intensive | Art, custom fabrication, thin sheet metals |

| MIG Welding | Easy to learn, high deposition rate | Less suitable for thin materials, spatter issues | Automotive, manufacturing, general fabrication |

Step-by-Step Guide to Implementing Laser Welding in Your Production Line

Implementing laser welding in your production line can seem daunting, but breaking it down into steps can make the process manageable. Start by assessing your current manufacturing capabilities and identifying specific areas where laser welding could enhance efficiency or product quality. It’s important to evaluate the materials you commonly work with, as laser welding is especially effective with metals like steel and aluminum. Gathering input from your engineering and production teams can help pinpoint the best applications for this technology.

Once you have identified the right applications, the next step involves choosing the appropriate laser welder. Research different models and their specifications to find one that suits your production scale and product requirements. Consider factors such as power output, type of laser (fiber or CO2), and automation features. Following that, ensure your facility is prepared for the integration of laser welding equipment, which may involve infrastructure upgrades or workflow adjustments. Finally, invest in training for your operators to maximize the efficiency and safety of your laser welding processes. With careful planning and execution, laser welding can become a powerful asset in your manufacturing techniques.

Identifying Key Industries That Benefit from Laser Welding Innovations

Laser welding technology has become an integral part of several key industries, driving efficiency and innovation in modern manufacturing techniques. The automotive sector stands out as one of the primary beneficiaries, where the precision and strength of laser welding enhance the performance and safety of vehicle components. The increasing demand for lightweight yet robust structures has led manufacturers to adopt laser welding for critical parts, like door rings, that provide both strength and weight reduction.

Another vital area is aerospace, where high precision and reliability are paramount. Laser welding allows for the seamless fusion of materials, which is essential for ensuring the structural integrity of aircraft components under extreme conditions. Additionally, the electronics industry utilizes laser welding for its ability to create fine, intricate joints without damaging sensitive components, ensuring the longevity and performance of electronic devices.

**Tips for Implementation:**

- When exploring laser welding, assess the specific requirements of your components to choose the appropriate technology and parameters.

- Consider investing in training for your workforce to ensure they are well-versed in the nuances of operating laser welding equipment, enhancing overall productivity.

- Stay updated on the latest advancements in laser technology to maintain a competitive edge and optimize production processes effectively.

Unveiling the Future: How Laser Welders Revolutionize Modern Manufacturing Techniques

Future Trends: What to Expect from Laser Welding Technology Advancements

The future of laser welding technology is set to transform modern manufacturing with remarkable advancements on the horizon. As industries explore innovative techniques, high-power lasers are leading the charge, enhancing precision and efficiency in welding processes. This evolution is particularly significant for sectors like automotive manufacturing, where the push for electric vehicles is driving the demand for advanced welding technologies. The integration of high-performance fiber lasers is optimizing production lines, enabling faster and cleaner joins.

Tips: Consider investing in training programs for your workforce to familiarize them with new laser technologies. Staying informed about the latest trends not only improves operational efficiency but also positions your company at the forefront of industry innovations.

Moreover, the laser welding machine market is projected to reach new heights, with forecasts indicating growth to USD 4.7 billion by 2035. This growth reflects a sustained interest in incorporating advanced laser solutions across various applications, including shipbuilding and offshore projects. As manufacturers adapt to these advancements, overcoming challenges such as deepwater welding techniques will require a comprehensive understanding of emerging technologies and collaborative approaches to problem-solving.

Tips: Collaborate with industry experts to identify potential challenges in adopting new technologies. Networking with peers can facilitate knowledge sharing and best practices that can enhance your operational capabilities.

Related Posts

-

Unlocking Precision and Efficiency with Handheld Laser Welders in Modern Manufacturing

-

Exploring the Future: How Handheld Laser Welders Are Revolutionizing DIY Projects

-

Revolutionizing Manufacturing: How Welding Automation Increases Efficiency by 30% and Reduces Costs

-

Exploring the Advantages of Hand Held Laser Welding Machines: Efficiency and Precision Unleashed

-

Understanding the Benefits of Laser Marking Technology in Modern Manufacturing

-

Unlocking the Future: How Micro Welders Are Revolutionizing Precision Manufacturing