Unlocking the Future: How Micro Welders Are Revolutionizing Precision Manufacturing

In an era where precision and efficiency are paramount, the advent of micro welders is poised to revolutionize the landscape of manufacturing. According to a report by MarketsandMarkets, the global micro welding industry is projected to reach $1.5 billion by 2025, reflecting a compound annual growth rate (CAGR) of 8.3%. This remarkable growth can be attributed to the increasing demand for high-quality, precise manufacturing techniques in sectors such as electronics, automotive, and medical devices.

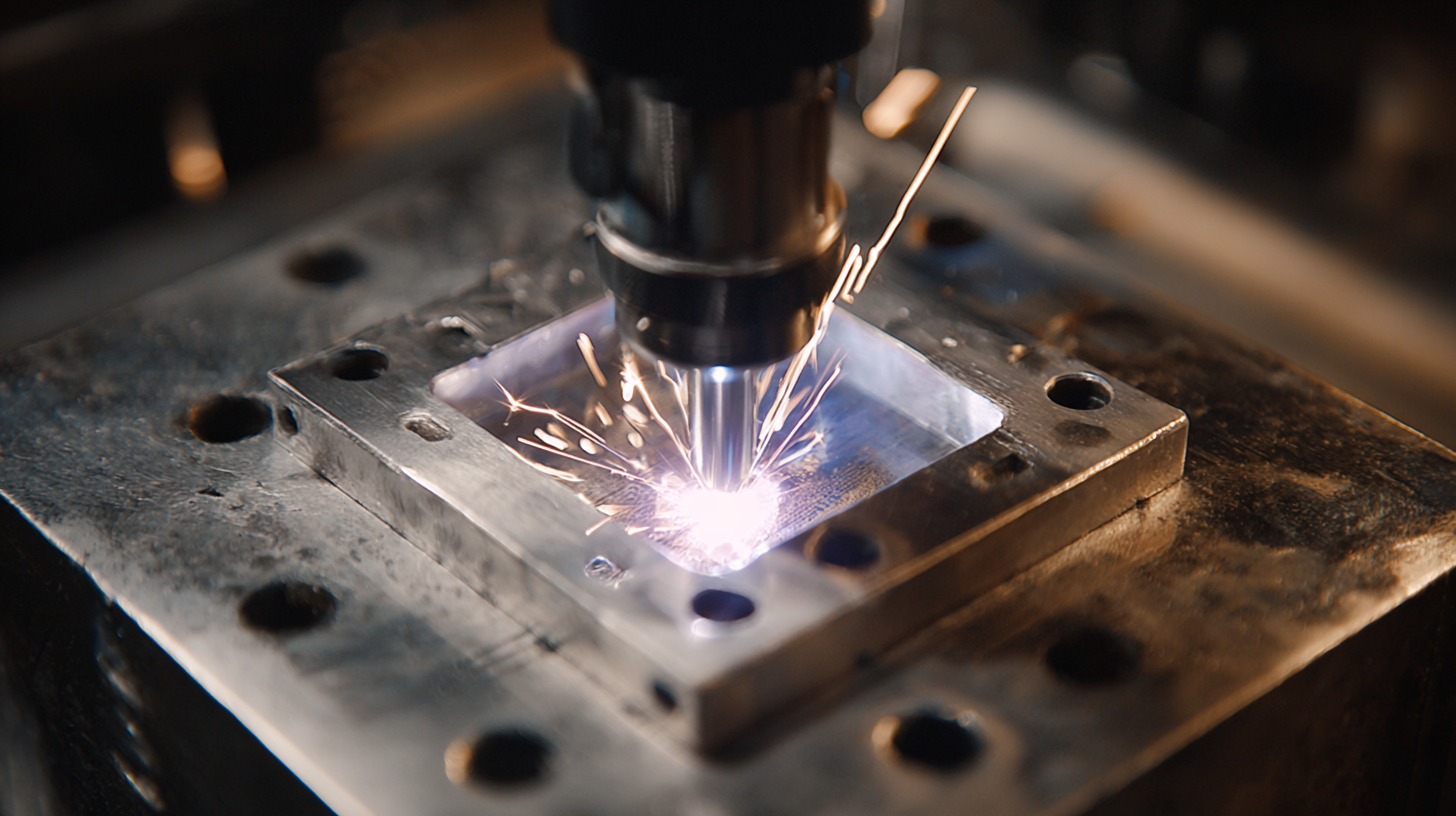

Micro welders, with their ability to deliver accurate and minimal heat input, ensure the integrity of delicate components while reducing material waste. As manufacturers strive for enhanced productivity and reduced operational costs, the integration of micro welding technology stands as a game-changer, paving the way for innovative applications and superior product reliability.

Understanding Micro Welding Technology: A Comprehensive Guide

Micro welding technology is transforming precision manufacturing by offering unmatched accuracy and control in joining small components. This technique, characterized by the use of low-energy laser beams, enables manufacturers to create intricate assemblies that were previously challenging to achieve. According to a report by MarketsandMarkets, the micro welding market is projected to reach $1.85 billion by 2025, growing at a CAGR of 8.3%. This growth is largely fueled by the increased demand for precision-engineered products in sectors such as electronics, automotive, and medical devices.

To maximize the benefits of micro welding, consider these tips: First, always ensure proper material compatibility. Different materials require specific welding techniques and settings for optimal results. Second, invest in regular maintenance of welding equipment. Well-maintained machines provide consistent performance and improve overall production efficiency. Lastly, utilize advanced monitoring systems to track weld quality in real time, preventing defects before they affect the final product.

With advancements in micro welding technology, precision manufacturing is not just about creating parts but also about enhancing their reliability and performance. As industries continue to adopt this innovative approach, the potential for reducing waste and increasing production speed becomes a key advantage, paving the way for more sustainable manufacturing practices.

Unlocking the Future: Micro Welding Technology in Precision Manufacturing

Key Benefits of Micro Welders in Precision Manufacturing Processes

Micro welders are rapidly transforming precision manufacturing by offering unparalleled benefits that enhance productivity and quality. One of the standout advantages of micro welding is its ability to join small components with exceptional accuracy. According to a report by MarketsandMarkets, the global micro welding market is projected to reach $400 million by 2025, growing at a CAGR of 5.7%. This growth is driven by increasing demand in industries such as electronics, automotive, and medical devices, where precision and the integrity of connections are paramount.

Micro welders are rapidly transforming precision manufacturing by offering unparalleled benefits that enhance productivity and quality. One of the standout advantages of micro welding is its ability to join small components with exceptional accuracy. According to a report by MarketsandMarkets, the global micro welding market is projected to reach $400 million by 2025, growing at a CAGR of 5.7%. This growth is driven by increasing demand in industries such as electronics, automotive, and medical devices, where precision and the integrity of connections are paramount.

Additionally, micro welders facilitate reduced thermal distortion, which is critical for maintaining the integrity of sensitive materials. With the ability to apply heat precisely at the weld site, manufacturers can minimize damage to surrounding areas, a key factor in high-tech industries where component performance is vital. A study published by the Institute of Electrical and Electronics Engineers (IEEE) highlights that micro welding can improve joint strength by up to 30% compared to traditional welding methods.

Tips: Ensure you conduct thorough training for operators on micro welding machines to fully exploit their precision capabilities. Regular maintenance of equipment can help sustain optimal performance levels, reducing downtime and improving production flow. Lastly, always test welds with precision instruments to verify the reliability of the connections in critical applications.

Step-by-Step: Implementing Micro Welding in Your Production Line

Implementing micro welding in your production line can significantly enhance quality and efficiency. According to a report by Grand View Research, the micro welding market is expected to reach $1.5 billion by 2025, driven by its applications in precision manufacturing across various sectors including aerospace, electronics, and medical devices. This technique allows for joining materials with pinpoint accuracy, minimizing heat-affected zones which is critical for high-performance applications.

To successfully integrate micro welding into your operations, begin by assessing your current production capabilities. Identify areas where precision joining is required and determine the specifications needed for your products. Invest in high-quality micro welding equipment designed for your specific materials and ensure your team is trained in the latest techniques to utilize these tools effectively.

Tips: Start with a pilot program to test the micro welding process on a small scale before full implementation. Monitor performance metrics closely to refine the process and address any challenges early on. Additionally, collaborate with suppliers who specialize in micro welding solutions to receive guidance on best practices and the latest technology advancements.

Troubleshooting Common Micro Welding Challenges in Manufacturing

Micro welding has emerged as a critical technology in precision manufacturing, enabling the assembly of intricate components with remarkable accuracy. However, as with any advanced manufacturing process, it is not without its challenges. One common issue faced by manufacturers is the struggle with proper heat management. In micro welding, excessive heat can lead to distortion or damage of sensitive materials. Careful control of power settings and the use of advanced cooling techniques can mitigate this risk, ensuring that the welded joints maintain structural integrity.

Another frequent challenge involves the selection of appropriate welding materials. The compatibility of materials significantly influences the quality of the weld. Mismatched material properties can result in poor weld strength and performance. Manufacturers must conduct thorough material assessments and consider factors such as thermal expansion and melting points when choosing welding electrodes and filler materials. By addressing these common micro welding challenges, manufacturers can unlock the full potential of this technology, leading to improved precision and enhanced product quality.

Unlocking the Future: How Micro Welders Are Revolutionizing Precision Manufacturing - Troubleshooting Common Micro Welding Challenges in Manufacturing

| Challenge | Description | Solution | Impact on Efficiency |

|---|---|---|---|

| Heat Affected Zone (HAZ) | Excessive heat can lead to distortion or damage in the material. | Optimize welding parameters and use precise control measures. | Reduces scrap rate and improves overall product quality. |

| Porosity | Gas pockets trapped in the weld can weaken the joint. | Ensure clean surfaces and control environmental conditions. | Increases weld integrity and reduces rework. |

| Misalignment | Misaligned components can lead to weak or ineffective welds. | Implement precise alignment tools and fixtures. | Improves weld quality and reduces time spent on adjustments. |

| Weak Joints | Weld joints that do not meet strength requirements. | Adjust parameters and conduct thorough materials testing. | Enhances reliability and reduces failures in applications. |

| Thermal Cycling | Repeated heating and cooling can weaken welds. | Use heat treatment methods post-welding to relieve stresses. | Increases durability in high-temperature applications. |

Future Trends: Innovations in Micro Welding Technologies to Watch

The landscape of precision manufacturing is rapidly evolving, driven by advancements in micro welding technologies. As industries continue to demand higher precision and efficiency, innovations such as laser micro welding and ultrasonic micro welding are surging to the forefront. Laser micro welding, characterized by its ability to create precise and clean welds in materials as thin as a human hair, allows for intricate assembly in applications like electronics and medical devices. This technology not only enhances production speed but also minimizes thermal distortion, leading to better-quality outcomes.

Additionally, the rise of automated micro welding systems is transforming production lines across various sectors. These automated solutions integrate artificial intelligence and machine learning, enabling adaptive welding processes that optimize parameters in real-time. With the potential to reduce human error and increase repeatability, these technologies are poised to streamline manufacturing operations significantly. As research continues and new materials emerge, the future of micro welding promises even more groundbreaking applications, ensuring that precision manufacturers are well-equipped to meet the challenges of tomorrow.